Description

Mud Control Mats

Quick, Effective Mud Management—No Base Required

Tired of mud? Our new Mud Mats offer a simple, durable, and instantly effective way to stabilize muddy ground—without the need for ground prep, fill layers, or heavy equipment.

Whether you’re managing muddy paddocks, feeding areas, or walkways, these interlocking panels are your go-to solution for both permanent and temporary mud control.

Mud Mat Uses

Mud Mats are a versatile solution for stabilizing muddy, high-traffic, or erosion-prone areas around your property. Use them anywhere you need a solid, safe surface—without the hassle of ground prep. Whether installed temporarily or permanently, they offer long-lasting performance and flexibility for a wide range of applications.

- Muddy paddocks and corrals

- Gate and entryways

- Feeding areas and turnout zones

- Shelter entrances

- Walkways, footpaths, and drive lanes

- Storage zones and access routes

- Landscaping, gardens, or parking spaces

- Event grounds, fairs, and seasonal installations

Key Features & Benefits:

Drainage & mud control

Safety & longevity

Stabilize the ground and prevent erosion

Low maintenance and easy to install

A Low-Maintenance Mud Control System

Built-In Drainage & Soil Protection

Mud Control Grids double as drainage panels, allowing excess water to flow through and away from the surface. This keeps walkways and turnout areas usable year-round while helping retain ground moisture during dry spells.

Their reinforced connection system evenly distributes weight, reducing pressure on the soil. This promotes long-term soil health and reduces surface compaction—an important consideration in sustainable farming and animal management.

Animal-Friendly Mud Control

Mud Control Grids are ideal for horses, cows, sheep, and other livestock. By stabilizing wet or uneven ground, the grids reduce strain on hooves, encourage natural movement, and help minimize injury and illness caused by unstable footing.

Important: When used in animal areas, a top layer of sand, mulch, or wood chips is recommended for comfort and safety.

Built for All-Season, All-Weather Use

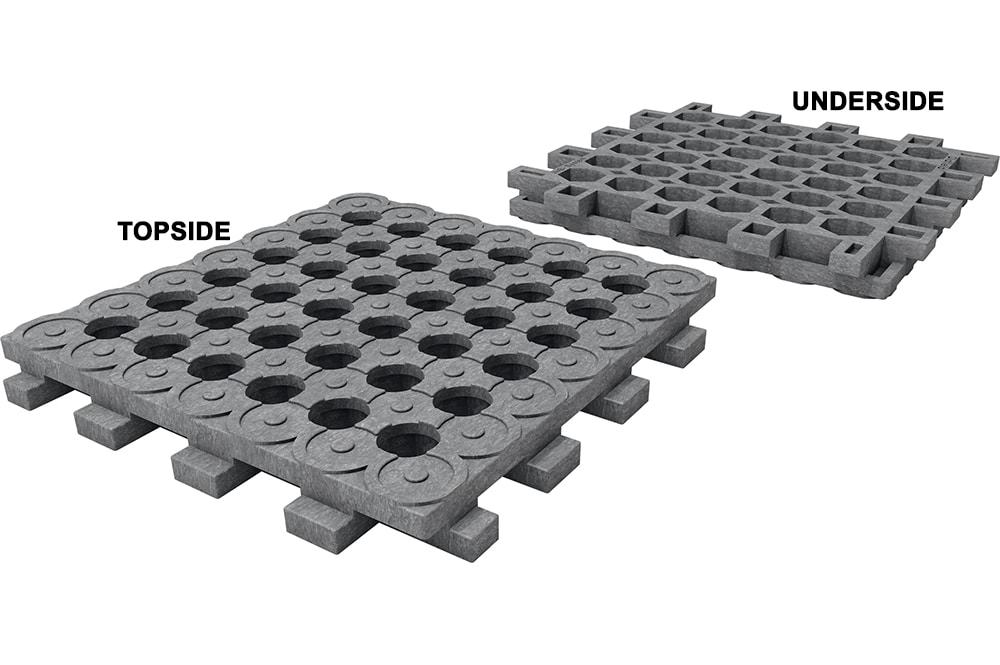

Designed for durability in any climate, Mud Control Grids are UV- and frost-resistant and will not degrade, crack, or rot. The hollow chamber structure acts as an air reservoir, improving buoyancy and preventing the panels from sinking.

If turned upside-down, the chamber system can even retain moisture, serving as a dust-control solution for dry climates.

Sustainable Ground Control

Mud Control Grids are an eco-friendly, cost-effective alternative to traditional ground reinforcement systems. Designed to work with the natural environment, they preserve soil quality, enhance drainage, and help maintain animal health.

Why Choose Mud Control Grids?

- No base prep required – install directly on soil

- DIY-friendly – quick setup with interlocking tabs

- Strong & long-lasting – supports up to 5.6 tons per sq ft

- Safe for animals – anti-slip surface with optional top layer

- 100% recycled plastic – weatherproof and environmentally conscious

- Versatile – use permanently or move and re-use as needed

- Low maintenance – won’t rot, break down, or require constant upkeep

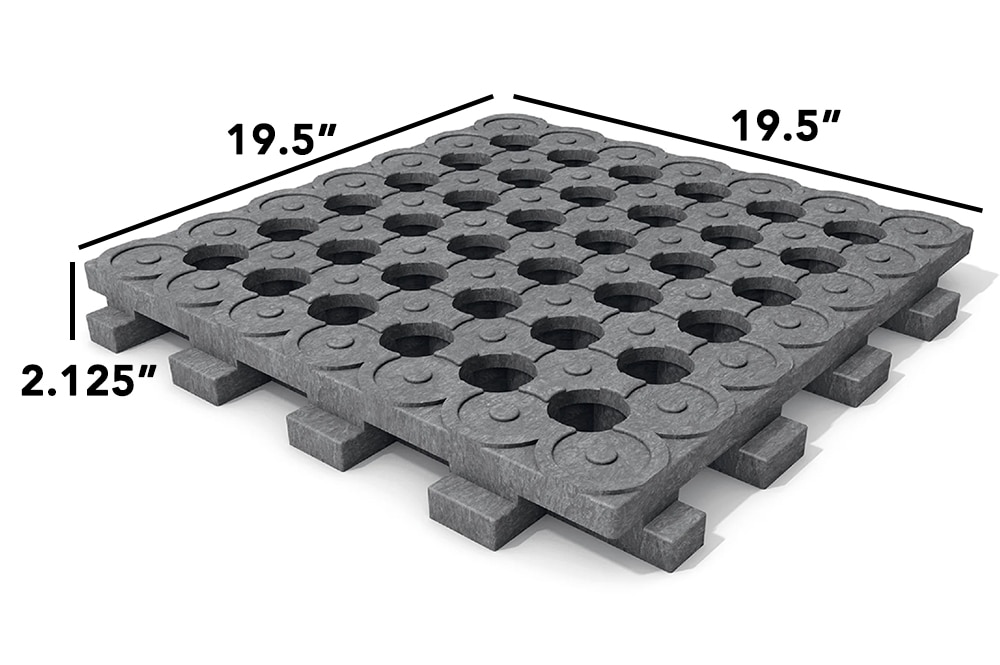

Mud Control Grid Details

Mud Grid mats are made from 100% recycled plastic, safe for animals and the environment.

Easy Installation & Flexibility

Mud Control Grids feature a plug-and-lock system and a hollow chamber design that prevents sinking—even on soft, muddy terrain. These panels can be placed directly on the ground and do not require any compaction, fill, or sub-base.

Grids can be topped with sand, wood chips, mulch, or coarse gravel for added comfort and drainage. For a green surface, you can even sow grass seed into a thin top layer of soil or sand.

These grids are easy to remove, reposition, or expand as needed—perfect for growing farms or temporary installations.