All About Horse Arena Sand

Sand qualities affect the performance of your surface, such as being soft, hard, or just right; how much dust is produced; and how it mixes with textile and rubber products.

Get Started with a Free Arena Sand Analysis

This is a valuable step and it’s easy! Our sand analysis data will:

Explain issues you may be having with your existing surface.

Ensure compatibility with Premier Footing Products.

Help you understand how other solutions will improve your surface (moisture, maintenance, dust control, etc.).

Ensure that the sand you purchase matches the report from your local quarry.

Getting Started

Many of our products can improve existing sand whether it’s too hard, compacted, dull, dusty, unstable, or doesn’t hold moisture, we have a variety of Footing Products to help.

Improve Your Existing Sand

To improve your existing sand get a free sand evaluation and report.

Buying New Sand

Premier Equestrian partners with quarries across the U.S. to make sure you get the best sand for your arena.

What sand is best for a horse arena?

There is no “arena sand.”

There are over 10,000 names of sand in the U.S. alone and not every sand is suitable for riding arenas. Quarries across the country will have different names for their sands and characteristics will vary.

Learn More About Sand Characteristics

Understanding sand particle shape, size, gradation, and mineralogy will help you to obtain the best outcome with your riding surface.

Particle Shape

Sand shapes affect how the grains nest together and affects stability underfoot.

Most sands will have a combination of shapes. We look at your sand under a microscope to get accurate information about what shapes are present.

Round Particles

Voids between round particles offer cushioning. However, they can roll like ball bearings, decreasing stability and traction.

Angular Particles

Sharp edges fit together tightly, providing stability and traction, but angular particles can compact and become hard.

Sub-Angular Particles

Sharp edges are worn off so particles nest while still allowing some movement. This lessens compaction and provides traction.

Particle Size

Sand is classified by its size. It’s smaller than gravel, but larger than silt and clay. As sand breaks down over time it turns to dust.

Super Fine Silt/Clay

Less than 0.074 mm; Sieve smaller than #200

Fine Sand

0.074 mm to 0.42 mm; Sieve #200 to #40

Medium Sand

0.42 mm to 2.0 mm; Sieve #40 to #1

Coarse Sand

2.0 mm to 4.76 mm; Sieve #10 to #4

Particle Grading

Gradation is the representation of different sized particles. This affects how much the sand compacts or remains loose. Textiles, rubber, and maintenance programs are common solutions to gradation issues.

Good Grading

A wide range of medium to small particles helps keep your footing stable, but not compacted.

Gap Grading

Large and small particles will separate becoming packed at the base and loose on top.

No Grading

When particles are the same size, sand remains loose and feels deep.

Gradation is measured by shaking a sample through a set of mesh sieves, large to small. The percentage of sand that passes each sieve is measured to create a sand gradation report.

Footing products, especially textiles, require specific gradations to perform properly.

Most equestrian sand suppliers will have prepared gradation reports for the different sands they sell.

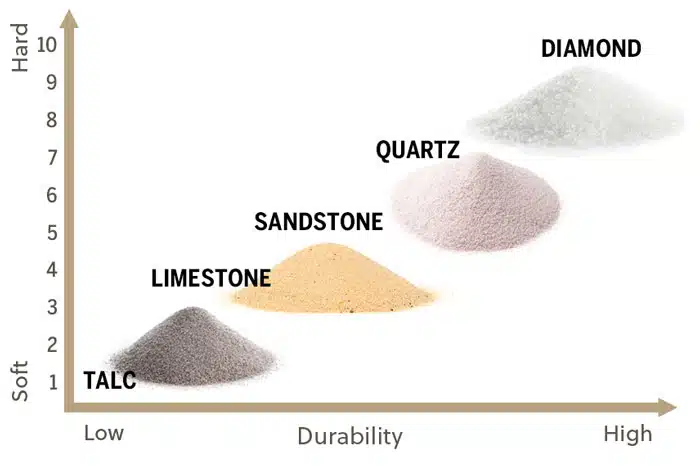

Mineralogy

Sand’s durability depends on its mineral type. As sand breaks down over time, it turns into airborne dust.

Quartz and Silica are commonly used for horse arenas because the particle hardness. Different regions of the country will affect what minerals are available.

Where Does Sand Come From?

Natural Sand

Natural sand erodes from mountain rock. The host rock determines the exact mineral, but most sand is composed of silica from broken down quartz crystals.

This type of sand is extremely resistant to breakdown due to its chemical hardness and will last longer in arena footing.

These hard sand particles have been transported and tumbled by water, making them round or sub-angular in shape.

Manufactured Sand

Rock quarries crush rock into sizes ranging from 5mm to fine dust. Mineral composition can range widely. They may be softer and break down to dust sooner.

The fines and are sold as ‘manufactured sand,’ ‘man-made sand,’ ‘crusher fines,’ or ‘stone dust.’

These particles are sharp and will compact tightly if used alone. A small amount of manufactured sand can add stabilization to footing with very round sand.

Get Started

Many of our products can improve existing sand whether it’s too hard, compacted, dull, dusty, unstable, doesn’t hold moisture, and more. Improve your existing sand, or talk to us before you buy new. We’ll guide you so you know exactly what to ask your local quarry.

Improve Your Existing Sand

Start with a free sand evaluation and report.

Buying New Sand

Talk to us first. We can guide you to a qualified sand from our resource library.

Related to Footing Products

Premier Equestrian, Inc. does not make any warranties or representations of any kind, whether express, implied, or statutory, with respect to any service or product, including without limitation, warranties or representations concerning merchantability, non-infringement, fitness for a particular purpose, performance, quality, or that products or services will be error-free.